‘Let’s prepare for additional U.S. sanctions’… Chinese semiconductor manufacturers strengthen production capacity

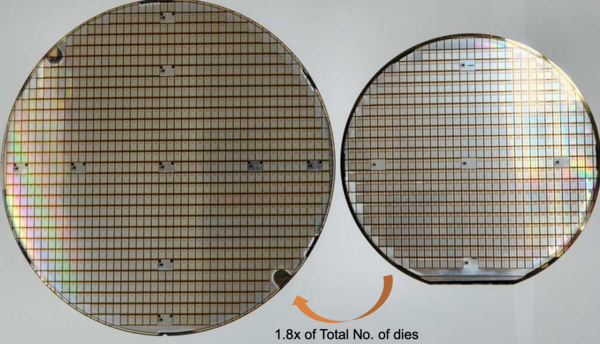

According to Hong Kong’s South China Morning Post (SCMP) on the 21st, SEMI’s recent report said that the production capacity of Chinese foundries (semiconductor consignment production) companies this year has increased by 15% to 8.9 million units per month, and will increase by 14% next year. It was predicted that the number would be 10.1 million.

SEMI said that this is well above the global average growth rates of 6% and 7%, respectively, over the same period.

As a result, the association predicts that China will account for about 30% of total global wafer production capacity next year.

ON Semi establishes SiC manufacturing facility in Czech Republic… Expansion of power semiconductor production

On Semi, the second-largest global power semiconductor company, announced on the 20th that it plans to establish a state-of-the-art vertically integrated silicon carbide (SiC) manufacturing facility in the Czech Republic.

SiC power semiconductors are essential components that control power conversion for electric vehicles, energy infrastructure, and high-output electric vehicle chargers, and demand is rapidly increasing due to the influence of artificial intelligence (AI) and the spread of electric vehicles.

To respond to the demand for advanced power semiconductors, ON Semi will establish a new SiC manufacturing facility in the Czech Republic and produce intelligent power semiconductors. Onsemi explained that this investment is one of the largest private sector investments in Czech history.

iTech expands semiconductor testing business to AI and vehicles under 5nm

iTech announced on the 20th that it has completed the introduction of system semiconductor test equipment of 5 nanometers (nm) or less.

iTech’s main business is package testing and wafer testing of legacy semiconductors used in home appliances.

The company explained that it has the capability to test semiconductors under 5nm through the introduction of new equipment. He added that the company plans to use this as an opportunity to strengthen its sales activities not only in Korea but also in China, Taiwan, the United States, and Japan.

SK Key Foundry accelerates development of next-generation power semiconductor GaN

SK Key Foundry (CEO Lee Dong-jae), an 8-inch pure foundry semiconductor company, announced on the 19th that it has secured key device characteristics of the next-generation power semiconductor gallium nitride (GaN) and is accelerating its efforts to complete development within the year.

SK Key Foundry has focused on the marketability and potential of GaN power semiconductors and has formed a formal team in 2022 to develop the GaN process. It has recently secured the characteristics of 650V GaN HEMT devices and is accelerating with the goal of completing development within the year.

The 650V GaN HEMT has high power efficiency, which reduces the cost of heat dissipation devices compared to silicon-based products, so that the final customer’s system price does not differ much compared to existing silicon. This will be an advantage for fabless customers doing business in markets such as high-speed charging adapters, LED lighting, data centers, ESS, and solar micro inverters with silicon-based 650V products, a company official explained.

Trend Force “TSMC operation rate expected to exceed 100% in the second half of the year”

According to Trend Force, a Taiwanese market research company, on the 19th, TSMC is producing 5 nanometers (nm, 1 nm is 1 billionth of a meter), 4 nanometers, and 3 nanometers due to high demand for artificial intelligence (AI), high-performance computers (HPC), and smartphones. Full capacity is being utilized in the nano process.

TSMC plans to increase the price of high-demand, high-tech processes in consideration of costs resulting from overseas expansion and rising power prices.

Trend Force reported that Taiwanese foundry companies, excluding TSMC, have an average operating rate of 70-80% due to overall weak demand.

Wireless communication fabless unicorn attracts Series A investment worth 10 billion won

System semiconductor startup Unicorn announced on the 18th that it had attracted 10 billion won in Series A investment. This investment, led by Doosan Investment, was participated by Hanwha Investment & Securities and SV Investment. Existing investor RNs Venture Capital also continued its investment.

Unicorn is developing a wireless communication semiconductor-based transmission solution that replaces existing conductor-based connectors and cables. We are attempting to implement ultra-high-speed data transmission and reception of 10Gbps or more by utilizing integrated circuit design technology and electromagnetic wave-related technology.

3A Logics, NFC business MOU with System Base

3A Logics, a fabless company in the near field communication (NFC) field, announced on the 20th that it signed a memorandum of understanding (MOU) for NFC business cooperation with System Base, a company specializing in the Internet of Things (IoT).

According to the company, 3A Logics has been manufacturing NFC chips as its main business since its establishment in 2004. For the first time in Korea, we developed our own NFC reader chip and NFC tag chip. System Base was founded in 1987 and is a company that has accumulated know-how in developing various IoT products, including semiconductors, wireless communications, converters, and serials, for 37 years.

With the signing of this MOU, the two companies plan to cooperate in the development and commercialization of NFC-based industrial powerless locking devices (LOTO·Lock-Out∙Tag-Out) products.

Canada also plans to impose new tariffs on Chinese electric vehicles

Bloomberg News reported on the 21st (local time) that the Canadian government, led by Prime Minister Justin Trudeau, is preparing to impose new tariffs on electric vehicles made in China.

Citing anonymous officials, Bloomberg reported that the Canadian government is trying to keep pace with the United States and the European Union (EU), which have already announced additional tariffs on Chinese electric vehicles.

Bloomberg said that although a final decision on how to proceed has not yet been made, the Canadian government is expected to soon announce the start of a public hearing process on tariffs that will hit China’s electric vehicle exports.

Lotte Chemical develops high-strength, flame-retardant PP products for electric vehicle batteries

Lotte Chemical announced on the 20th that it has developed a high-strength, flame-retardant PP (polypropylene) plastic that can delay the thermal runaway phenomenon of electric vehicle batteries.

The main cause of fire in electric vehicles powered by lithium-ion batteries is the ‘thermal runaway phenomenon’ of the battery. This is a phenomenon in which the internal temperature of the battery increases by more than 1000°C in just a few minutes due to electrical shock such as physical shock, overvoltage, or overdischarge.

Accordingly, Lotte Chemical developed a material with short glass fibers (PP/SGF) and a material with improved rigidity with long glass fibers (PP/LGF).

Ecopro BM “Discussing sodium battery electric vehicles”

On the 19th (local time), EcoPro BM held a press conference explaining the cathode material for sodium-ion batteries at ‘InterBattery Europe’ hosted by the Korea Battery Association in Munich, Germany. Lee Dong-wook, head of EcoPro BM’s future technology division, said, “We are in close consultation with domestic automakers to launch electric vehicles equipped with sodium-ion batteries.” However, he explained, “The development of the cathode material is in the final stages, and we will have to wait and see the market situation before launching it as a battery for electric vehicles.”

Sodium ion batteries, also called sodium ion batteries, operate in a similar way to the lithium ion batteries that are currently most widely used. The difference is that it uses sodium instead of lithium to generate electricity. The advantage of sodium compared to lithium is that it can be easily obtained anywhere in the world, including in seawater and salt mines.

Cathode material exports, which had revived, fell again by 10%

According to the Korea Customs Service’s import and export trade statistics on the 17th, the export amount of ternary cathode materials in May was $548.96 million, a 9.5% decrease from the previous month ($617.76 million). Export weight also decreased by 10.4% to 20,847 tons compared to the previous month (23,268 tons).

Ternary cathode materials mainly refer to NCM (nickel, cobalt, manganese) and NCA (nickel, cobalt, aluminum) anode materials used by domestic battery manufacturers for electric vehicle batteries.

Exports of cathode materials, which had been on a downward trend since the beginning of the year, succeeded in rebounding by recovering to the $600 million range in April, but fell back to the $500 million range in just one month. The export amount of cathode materials in May is the lowest this year. The unit price of cathode materials export was $26.8 per kg, a slight increase compared to the previous month.

Innox EcoM, powder for silicon anode materials for secondary batteries, requests preliminary hearing for listing

According to the investment banking (IB) industry on the 21st, Innox EcoM recently requested a preliminary review for KOSDAQ listing. Considering that the screening process takes 2 to 3 months, listing on the KOSDAQ is expected to be possible in the fourth quarter of this year. Daishin Securities was in charge of the listing.

Inox EcoM is a company specializing in the manufacture of powder for secondary battery silicon (Si) cathode materials, established in 2007. Panasonic, Japan’s largest battery cell company, is its main customer. In Korea, it is expanding its sales scope to include Daejoo Electronic Materials, which it supplies to LG Energy Solution.

The public offering funds secured are expected to be used to expand production facilities to expand production. Innox EcoM’s Si powder production, which was around 30 tons per month in 2020, increased to 200 tons per month last year and plans to expand to 1,000 tons per month in 2027.

SK On Develops ‘Polymer Electrolyte’ for Lithium Metal Batteries

SK On has succeeded in developing a polymer electrolyte that can be used in lithium metal batteries, which are considered the next-generation batteries. Electrolyte is one of the four major elements of a battery (anode material, cathode material, separator, and electrolyte). Current lithium-ion batteries work on the principle that lithium ions move to the cathode to charge, and lithium ions from the cathode move to the anode to generate electrical energy.

Here, the material that plays a role in moving lithium ions to the positive or negative electrode material is the electrolyte. This time, a polymer electrolyte optimized for battery products in which the negative electrode material is made of solid lithium metal rather than the existing graphite or silicon has been developed. In particular, it is evaluated that this electrolyte development has brought us one step closer to the development of solid-state batteries as well as lithium metal batteries.

SK On announced on the 16th that it has jointly developed ‘SIPE (single-ion conducting polymer electrolyte)’, a new polymer electrolyte for lithium metal batteries that can be used at room temperature, with a research team at the University of Texas.

Here we go, self-driving robot delivery testing starting in August

Delivery app Yogiyo announced on the 21st that it will begin testing outdoor autonomous robot delivery in Songdo, Incheon starting in August.

To this end, Yogiyo signed a business agreement with Newbility, a self-driving robot service company, for the self-driving robot delivery service business. The two companies decided to cooperate in joint development of robot delivery services, linking of related systems, and marketing.

Within the autonomous robot delivery test area, when a customer orders a menu from a store that supports robot delivery through the Yogiyo app, the robot determines the customer’s location and delivers it to the designated location.

SK Shielders starts autonomous vehicle security business

SK Shielders announced on the 21st that it has signed a collaboration with CPSIX to expand the self-driving car security business.

While the mobility security market is growing at more than 18% per year, SK Shielders, No. 1 in information security in Korea, will begin providing mobility security services, including checking vulnerabilities in self-driving cars, through technical cooperation with promising startup CP6.

The two companies will cooperate in promoting self-driving vehicle vulnerability inspection projects. This is because in order for self-driving cars to operate safely on actual roads, it is important to detect and prevent security threats in advance.

Oisolution develops 5D FMCW lidar system

Oi Solutions, a company specializing in optical communication solutions, announced on the 20th that it will speed up the development of the ‘next-generation wide angle 5D LiDAR system’ through a national project.

A total government budget of 4 billion won was invested in the ‘Next Generation Wide Angle 5D LiDAR System’ national project. SOS Lab, a rider specialist company, participates as the host organization. The joint participating organizations were Oi Solution and Ramdino Vision.

In this project, Oisolution supports the development of core technologies, such as FMCW (frequency modulated wave) laser and optical engine for interference signal processing.

IL Science begins developing new lens materials for next-generation lidar

IL Science, a smart optical solution specialist, announced on the 17th that it signed a business agreement with SOS Lab and First Optics to develop ‘next-generation LiDAR (detection and distance measurement through light) new material optical lens’. Through this agreement, IL Science will be responsible for producing lenses and lamps with higher transparency than existing lenses and reduced size and weight.

SOS Lab will be responsible for manufacturing and selling LiDAR, while First Optics will be responsible for optical design.

Autonomous A2G signed an agreement with Seongnam City for a ‘mobility specialized city creation project’

Autonomous A2G announced on the 17th that it signed a business agreement (MOU) with Seongnam City on the 14th to promote the ‘Mobility Specialized City Creation Project’.

Seongnam City, which was selected for the Ministry of Land, Infrastructure and Transport’s 2023 mobility specialized city development project, has ▲Seongnam-type integrated mobility (MaaSMobility as a Service) platform ▲local customized mobility hub ▲resident open sharing service for official/affiliated vehicles ▲personal mobility service ▲autonomous shuttle service ▲We plan to build autonomous driving LiDAR infrastructure services (C-ITS).

Autonomous A2G is responsible for establishing self-driving shuttle services and developing self-driving lidar infrastructure services among Seongnam City’s plans.

OLED panel growth for iPad… Samsung D and LGD performance expected to improve in the second quarter

According to market research company DSCC on the 19th, global OLED tablet panel shipments in the second quarter of this year are expected to increase by 333% compared to the same period last year to more than 3.9 million units.

OLED tablet panel shipments in the first quarter reached 1.72 million units, an increase of 131% compared to the same period last year, reaching an all-time high. With the launch of Apple’s iPad Pro in full swing, the record is expected to be broken in the second quarter. DSCC predicted that shipments in the second quarter would increase by 127% compared to the first quarter.

As Apple applied OLED panels to the iPad for the first time, the related market expanded. DSCC analyzed that the iPad Pro M4 13-inch product released by Apple drove the growth of the OLED tablet panel market.

T-Robotics commercializes the world’s first 8.6G OLED deposition process traveling vacuum robot

T-Robotics, a domestic robot development and manufacturing company, announced on the 18th that it has early achieved the performance of an 8.6G vacuum robot for the OLED (organic light-emitting diode) deposition process and has entered the commercialization stage.

The 8.6th generation vacuum robot developed this time was achieved through the Materials and Parts Technology Development Project of the Ministry of Trade, Industry and Energy. It is a large-scale project with a total project cost of 21.5 billion won over four years. Several companies, including large domestic companies, participated, and T-Robotics was in charge of overall management. The original development period was until December 31, 2024, but this is an early achievement that has been advanced by about 7 months.

CEO Seungwook Ahn said, “The significance of this OLED 8.6G vacuum robot development is that it allows us to compete in the robot market, which was monopolized by Japanese companies in the display industry market.”

Source: kipost.net