TSMC to Build Five More Advanced Packaging Factories in Taiwan

Taiwanese media outlets, including Liberty Times, reported on the 19th that Taiwan Semiconductor Manufacturing Company (TSMC), the world’s largest foundry (semiconductor contract manufacturing), plans to build four additional state-of-the-art packaging (AP) factories.

According to sources, Hou Yongqing, TSMC’s senior vice president and deputy co-chief operating officer, is expected to announce on the 22nd the addition of four advanced AP factories in the Tainan area of the Chiayi Science Park and Southern Science Park.

The source said that TSMC plans to begin mass production at its AP Plant 1 (P2) in the Ziyi Science Park in the first half of this year and bring in equipment to Plant 2 (P2).

IST to supply automated wafer sorting, classification, and transport equipment to SK Hynix.

On the 22nd, IST announced through a public notice that it had signed a contract with SK Hynix to supply semiconductor automation equipment.

The equipment being supplied this time is a sorter used in semiconductor manufacturing processes, an automated device that sorts, classifies, and transports wafers. IST explained that it has enhanced the precision and reliability of its wafer handling robots, thereby strengthening their automation capabilities.

Micron acquires Taiwanese semiconductor plant, expanding DRAM production.

According to Micron on the 19th (local time), the company recently signed a letter of intent to acquire the ‘P5 factory (P5 fab)’ of semiconductor company PSMC in Miaoli County, Taiwan for $1.8 billion in cash.

Micron said the deal will allow it to increase DRAM production starting in the second half of next year.

The company said the acquisition, which includes its existing 300,000-square-foot (27,871 m2) 300mm fab cleanroom, will further strengthen Micron’s position to meet growing global memory demand.

Toyota and other Japanese automakers collaborate to secure a stable supply of semiconductors.

Japanese automakers, including Toyota Motor Corp., plan to cooperate and share related information to ensure a stable supply of semiconductors, the Nikkei newspaper reported on the 22nd.

According to the newspaper, the Japan Automobile Manufacturers Association and the Japan Automobile Parts Industry Association, which include Toyota and Honda Motor, plan to establish a system to share semiconductor information in April.

The Automobile and Battery Traceability Promotion Center, a general incorporated association, is expected to be in charge of actual operations.

Samsung Electro-Mechanics: “Glass substrate projects with multiple clients…Joint venture to be established in the first half of the year.”

Samsung Electro-Mechanics announced on the 23rd regarding its glass substrate business, a next-generation growth engine, that it “built a pilot line last year and has been promoting it to various big tech clients through the development of element technologies and sample production,” and that “we are currently working on projects with multiple clients.”

Samsung Electro-Mechanics announced this during a conference call announcing its fourth-quarter 2025 performance this afternoon, saying, “The establishment of the joint venture (with Japan’s Sumitomo Chemical) will be completed within the first half of the year.”

In November of last year, Samsung Electro-Mechanics signed a memorandum of understanding (MOU) with Sumitomo Chemical Group to review the establishment of a joint venture (JV) to manufacture glasscore.

FNS Tech decides to invest in a mass production line for CMP pads for semiconductor glass substrates.

FNS Tech announced on the 21st that it is building a mass production line for large-area chemical mechanical polishing (CMP) pads for semiconductor glass substrate manufacturing. CMP pads are a key material component for planarizing substrates.

The company produced prototype CMP pads for glass substrates in September of last year and supplied them to a customer in December. They are currently undergoing testing.

In the semiconductor glass substrate manufacturing process, substrate planarization determines production yield. To achieve this, the CMP process, which flattens the substrate after plating, is essential.

NVIDIA Invests $200 Million in AI Inference Startup

The Wall Street Journal (WSJ) reported on the 20th (local time), citing sources, that Nvidia invested $150 million (approximately 220 billion won) in Baseten, a startup specializing in AI ‘inference’.

Sources reported that Baseten raised $300 million (approximately 440 billion won) in a funding round led by venture capital firm IVP, with NVIDIA contributing $150 million. In December of last year, NVIDIA signed a technology licensing agreement with Groq, a startup specializing in AI accelerator chip design.

A bird’s-eye view of the cathode material plant being built by POSCO FutureM. / Source: POSCO FutureM

SK Signet Consortium Completes Robot-Based Rapid Charging Demonstration for Electric Vehicles

SK Signet announced on the 21st that it has implemented a technology that allows a robot to recognize the location of a vehicle and automatically connect the charging connector through the ‘Robot-based Electric Vehicle Rapid Automatic Charging System Development and Verification’ consortium.

This study involved 10 organizations, including SK Signet, Korea Institute of Machinery and Materials, Korea Automotive Research Institute, Korea Electrotechnology Research Institute, Korea Smart Grid Association, Korea Electronics Technology Institute, Korea University, Zeus, Cmes, and Gridwiz.

The consortium conducted a long-term demonstration of a 400 kW (kilowatt) robot charging system, verifying key requirements for commercialization, including charging precision, compliance with international communication and payment standards, and safety.

GI Tech signs a slot die supply contract with a North American global battery company.

GITECH announced on the 23rd that it has received a slot die supply order (PO) worth approximately KRW 2.5 billion (USD 1.72 million) from a global top-tier battery cell manufacturer with production bases in North America.

According to the company, the product being supplied this time is a slot die, a key component in the secondary battery electrode process. It plays a vital role in ensuring the uniform and precise application of active materials during battery manufacturing. Based on its ultra-precision processing technology, GI Tech has met the strict quality standards of its customers, maintaining an ongoing partnership.

POSCO FutureM CEO Eom Ki-cheon appointed as chairman of the Korea Battery Industry Association.

According to the battery industry on the 23rd, the Korea Battery Industry Association will put on the agenda a motion to appoint CEO Eom Ki-cheon as the 9th president of the association at the board meeting scheduled for the 11th of next month.

The current chairman of the Korea Battery Industry Association, Kim Dong-myeong, is nearing the end of his term as president of LG Energy Solution. Kwon Young-soo, former vice chairman of LG Energy Solution, was appointed in 2023 and upon his retirement from the company. Under the automatic succession provisions of the association’s articles of incorporation, he was appointed chairman in February 2024.

CNP Advanced Materials Technology to Invest KRW 500 Billion to Build a Cathode Materials Manufacturing Facility in Pohang

CNP Advanced Materials Technology, a battery materials manufacturer, is investing 500 billion won to build a new factory in Pohang. North Gyeongsang Province and Pohang City signed an investment agreement with CNP Advanced Materials Technology on the 19th at Pohang City Hall.

CNP Advanced Materials Technology is a company with shareholders including global secondary battery materials company Pino and POSCO Future M. The company is recognized for its technological prowess and business capabilities, enabling the simultaneous production of ternary (NCM – nickel, cobalt, manganese) precursors and LFP cathode materials.

Nanosilicane Advanced Materials is in the final stages of preparations to supply silicon anode materials to Cellmaker.

Nanosilicane Advanced Materials announced on the 23rd that it is currently producing and verifying samples using its own facilities and plans to complete final preparations for supplying silicon anode material samples by the end of this month.

In November of last year, Nanosilicane Advanced Materials successfully completed performance verification of its silicon anode material from a government-affiliated electronics and IT research institute. In December of last year, the company also formalized its technological collaboration by signing a non-disclosure agreement (NDA) with three domestic cell manufacturers.

Polaris Sewon wins order for key components for next-generation large electric vehicles.

Polaris Sewon announced on the 19th that it has signed a contract to supply header condensers for the ‘next-generation large electric vehicle’ to be unveiled by the largest domestic automaker through a key parts subsidiary of a major domestic automobile group.

This component is scheduled to enter full-scale mass production starting next year and be supplied to the global market. The header condenser is a key air conditioning component that maximizes the vehicle’s thermal management efficiency. With this order, the company is successfully restructuring its business portfolio from its existing focus on internal combustion engines to focus on components specifically for electric vehicles (EVs).

Enchem: “China Supply Expected to Increase 300% This Year”

Electrolyte specialist Enchem announced on the 23rd that it expects its electrolyte supply in China this year to increase by approximately 300% year-on-year, driven by the rapid growth of the Chinese battery energy storage system (BESS) market and the acquisition of new customers.

Enchem’s Chinese subsidiary supplied approximately 38,000 tons of electrolyte to China last year, a more than 70% increase from the previous year. With CATL’s supply starting in the second quarter of this year, the Chinese market supply is expected to increase by 300% year-on-year to approximately 150,000 tons this year.

Dongwha Electro signs a purchase agreement with Pgt for key electrolyte materials.

Dongwha Electrolyte, a subsidiary of Dongwha Enterprise and specialized in electrolytes, announced on the 20th that it has signed an equity investment and raw material purchase agreement with Pgt (formerly Progreentech), a specialty chemical company. This decision is aimed at securing competitiveness in the North American market by internalizing key materials during a time of supply chain restructuring.

PGT possesses the manufacturing technology and production capacity for high-purity lithium hexafluorophosphate (lithium salt), a key electrolyte material. The company has adopted environmentally friendly technology in its manufacturing process, minimizing waste generation and enabling the recycling of byproducts.

Hyundai Motor Company’s union protests robots with annual salaries of 14 million won.

On the 22nd, the Hyundai Motor Company labor union made clear its opposition to the introduction of humanoid robots into production, stating, “Not a single one will be introduced without agreement.” If Hyundai Motor Group attempts to introduce robots into production in the future, conflict and tension between labor and management are expected to intensify.

Hyundai Motor Group’s strategy to dominate physical AI, led by the globally acclaimed humanoid robot “Atlas,” appears to have hit an internal snag.

Musk: “Panda, a humanoid robot, will be available next year”…Robotaxis to spread across the US by the end of the year

According to foreign media outlets such as CNBC and CBS, Musk attended the World Economic Forum (WEF) in Davos, Switzerland on the 22nd (local time) and predicted that robots will eventually outnumber humans. He said that as robotics permeate our daily lives, the global economy will experience “explosive growth,” and that “my prediction is that there will be more robots than people.”

He added, “Robotics and artificial intelligence (AI) are the path to prosperity for all,” and “AI and robotics are the only way to solve the problem of global poverty and provide a high standard of living for all.”

KH Vatec and Eastern Gear Sign MOU to Advance High-Precision Reducers for Robots

KH Vatech announced on the 23rd that it signed a ‘Memorandum of Understanding (MOU) for cooperation in advancing and commercializing high-precision reducer technology for robots’ with Eastern Gear.

This agreement was pursued to combine the capabilities of the two companies through technological cooperation in the field of reducers, a core driving component of robots, and to develop and mass-produce competitive products based on this.

Mind AI partners with Thai AI company to supply quadrupedal robot platform.

Maum AI, which develops autonomous control and robotics technologies, announced on the 21st that it has signed a strategic partnership with Thai AI technology company Hatari NEXT Co., Ltd. and will promote the launch and supply of a quadruped robot platform targeting the Thai defense and security market.

In this collaboration, MindAI will provide core technologies for autonomy, cognition, and control, along with a quadrupedal robot platform, while the Thai partner will be responsible for local assembly, system integration, and business development in Thailand. The two companies have established a joint collaboration framework to enable rapid deployment of quadrupedal robot systems in real-world operational environments.

Hyundai Motor Group’s autonomous driving leader: “We’re going head-to-head with Tesla.”

Park Min-woo, President and Head of Advanced Vehicle Platform (AVP) Headquarters and CEO of Forty2Dot (pictured), who is the new autonomous driving commander of Hyundai Motor Group, said, “This year is a decisive turning point for the popularization of autonomous driving technology,” and “Win or lose will not be determined by who developed the technology first, but by who expands products that can be used faster and more reliably to the market.”

In his first message to executives and employees following his appointment on the 21st, CEO Park emphasized, “We must expedite commercialization to provide tangible value to customers.” Born in 1977, CEO Park, a former engineer who oversaw autonomous driving technology development at Tesla and Nvidia, was appointed on the 13th.

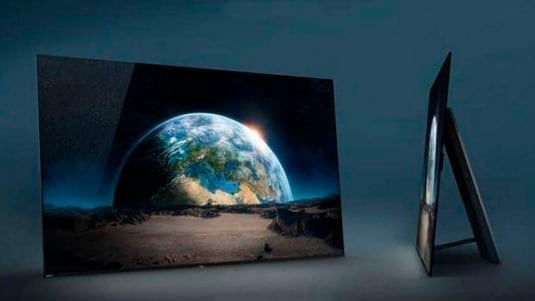

/Photo = Sony

The Power of Korean OLEDs Grows Apple’s Market Share

Samsung Display and LG Display will supply displays for Apple’s upcoming iPhone 18 series and foldable iPhones, which will be released this fall. Unlike the previous four models, the iPhone 18 series will only be released this year in two models: the Pro and Pro Max, and Samsung Display and LG Display are confirmed to supply these displays.

Although BOE entered the supply chain for the iPhone 17 series last year, it suffered setbacks due to quality issues late last year, and the iPhone 18 Pro and Pro Max, which will be released this year, are considered to be technically more difficult than their predecessors, making it virtually impossible for them to enter the market.

OLED orders from China are booming

Mirae Company, Narae Nanotech, and others have secured orders for equipment to be installed in BOE’s OLED factory under construction in Chengdu, Sichuan Province, China. BOE is investing 63 billion yuan (approximately 12 trillion won) in Chengdu to build its 8.6th-generation OLED plant, the “B16” line.

Mirae Company recently signed a contract to supply equipment worth 46.4 billion won to BOE’s Chengdu plant. The equipment Mirae Company will supply to BOE is reportedly an edge grinder, used to precisely process the edges of OLED substrate glass. Narae Nanotech also recently announced that it has signed an equipment supply agreement with BOE. However, at BOE’s request, the terms of the contract, including the amount, were withheld from public disclosure.

Japan’s Sony exits TV business, establishes TV joint venture with China’s TCL

Japan’s Sony is establishing a TV joint venture with China’s TCL. Sony, once the undisputed leader in the TV industry, is effectively withdrawing from its own TV business and transferring it to the joint venture.

TCL has been able to enter the premium TV market, leveraging the power of the Sony brand. Amidst the prolonged slump in the TV industry, China’s offensive against the Korean TV industry, which maintains its leading position, is expected to intensify.

Source: Kipost.net

Leave a Reply